Circuit control boxes - serial

Well after using the parallel controllers for a while and being limited to 24 lines or channels per computer and running extension cords everywhere, I realized there had to be a better way. About the same time I started learning how lighting professionals setup and configured their equipment. So I put together a few ideas, bounced them off of a couple other people, and came up with what you're about to read.

First let me explain the theories behind using these boxes. I'll even throw in a few illustrations.

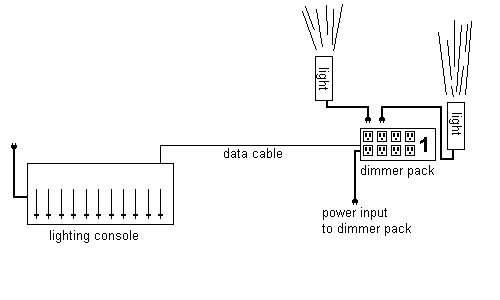

I learned about professional lighting equipment because of a Christmas program our church performed. I learned that one uses things called dimmer packs and a serial control language named DMX512. These dimmer packs are placed next to or very near your light sources. Each dimmer pack plugs into 110VAC and that's what provides power to the lights. Then all of these dimmer packs are connected together (daisy-chained together) by a low voltage control line, one end of which goes back to a control board. This control board sends serial data down the control line to each of the dimmer packs telling each pack what circuits or channels to turn on and off. Each pack has it's own starting address so the board can "talk" to an individual dimmer pack and the rest of the packs will ignore that data. Here's a simple picture:

Each outlet or circuit the dimmer pack controls is called a channel. The dimmer pack shown can control 8 circuits or channels. Because the starting address of the dimmer pack is 1, channels 1-8 are located on this dimmer pack. If the starting address of the dimmer pack was 5, then channels 5-12 would be on this dimmer pack. Each channel is associated with a slider on the lighting console. If you moved the #2 slider, the light connected to channel 2 would change.

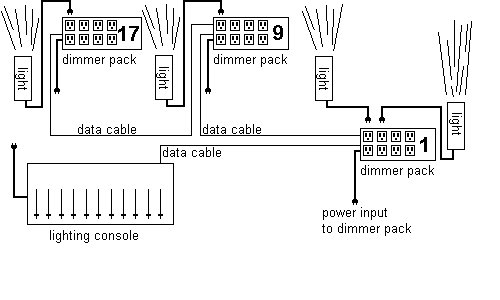

The advantages to this setup are one doesn't have to run extension cords from one place to every single light you want to control. You can run a single power cord to each dimmer pack from a power source (outlet) near the dimmer pack and then the data cable goes from the control board to the first pack, then the second pack and so on.

The other advantage (and this is a big one) is that one can address two different packs to have the same address. When one does this, both packs pay attention to the same data and thus both do the same thing, even if they are located far apart. Pretty neat, huh? Or you can overlap channels and only certain channels will behave the same. For example, if you set the starting address of one pack to 1 and the starting address of another pack to 8, then the last channel of the first dimmer pack and the first channel of the second dimmer pack would both behave the same. Here's another, more complex picture:

So after I learned all of this I recognized that I could use this in my design and control of my Christmas displays. After bouncing this idea off of a few people and refining it a bit (ok, A LOT) what we came up with were serially controlled control boxes with 8 channels in each of them and 1 additional always-on outlet. Of course one could make different varieties of these boxes (a few examples: one with only 2 channels, one with many many many channels,or drop the always-on channel, or any other type of box you'd like to make) but I felt one with 8 channels would be a good number to have for a given "control point" and having an always-on channel would be good for testing light sets or for displays where you'd need to have a few of the light sets always on.

This design differs from the professional setup in that you cannot overlap individual channels. You can only do this for a whole box at a time.

Ok! What makes these things work? Well since we are using the term "serially controlled" then yes, a personal computer (PC) of some sort is involved. The program (Dasher - see the Software link) runs on a PC and sends the data out the serial point. All of the control boxes are connected together using standard CAT5 network patch cables with male RJ45 connectors on each end. They are daisy-chained together. This means that one cable comes out of the computer and goes into a RJ45 connector on the first control box. Then another cable plugs into the second RJ45 connector on the first control box and runs to the second control box and so on. It doesn't matter which connector you plug into on the box. There is no difference between the two.

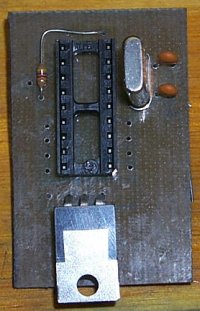

Inside each control box is a little PIC microprocessor that "listens" to the serial line and, when it hears it's address, turns each of the 8 channels in that box on or off according to the data sent to that box. Each PIC microprocessor has it's own address and that's how each box can be separately controlled. The following pictures show the circuit board without the PIC chip inserted into the socket. The 8 holes next to the socket go to the 8 optoisolators in the box. The second picture shows how small the circuit board is in relationship to the control box. It fits inside very easily.

Because there are 106 addresses available using the protocol we've developed and each address (control box) has 8 channels available, this means there is the functionality of controlling up to 106 x 8 = 848 channels. And that's using just one serial port. Most computers have at least two or more serial ports!

Return to HOME

Last modified on 02/01/01